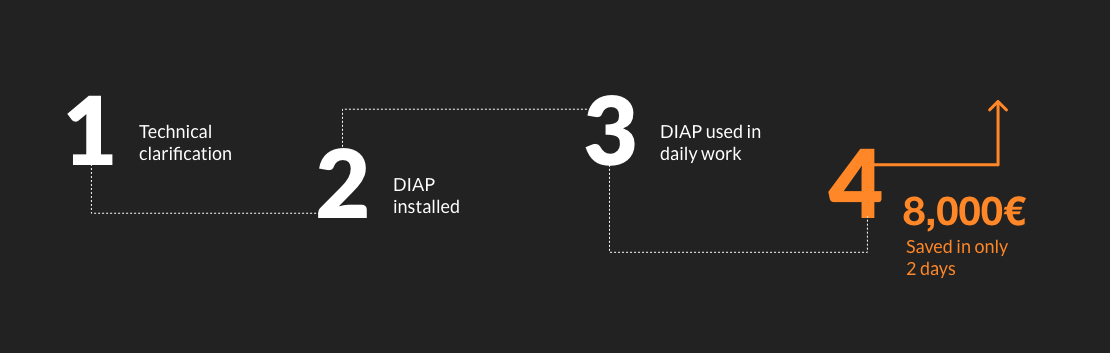

Learn how packaging manufacturer Smurfit Kappa benefits from DIAP

At Smurfit Kappa in Denmark, DIAP is used for collecting real-time data. The set-up was easy and in only 2 days, DIAP has saved the company for 8,000 EUR. The positive result has encouraged Smurfit Kappa to immediately install DIAP at a similar unit at one of their other Danish plants.