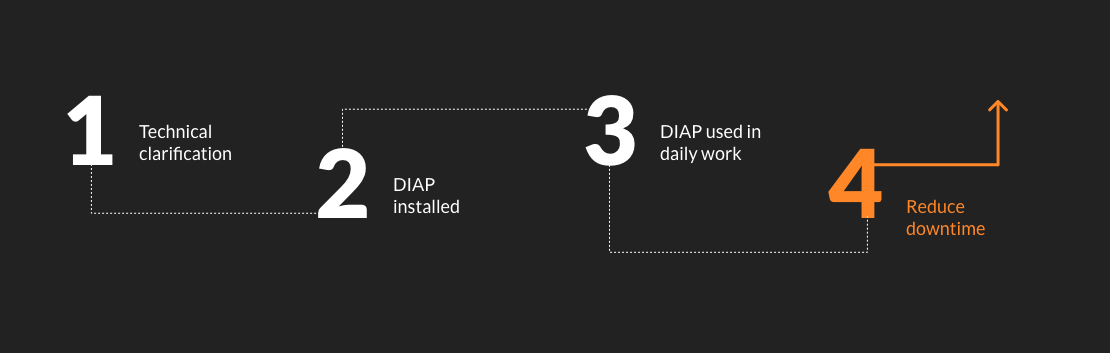

DIAP helps ensure smooth production at IBF

At IBF, DIAP is used to track stop causes in the production of enormous pipes that are used to guide the water away during rainstorms. The largest pipe weighs 7.5 tons. Tracking the stops digitally has given the company useful insight that helps reduce downtime. Now, IBF considers installing DIAP on other production lines as well.