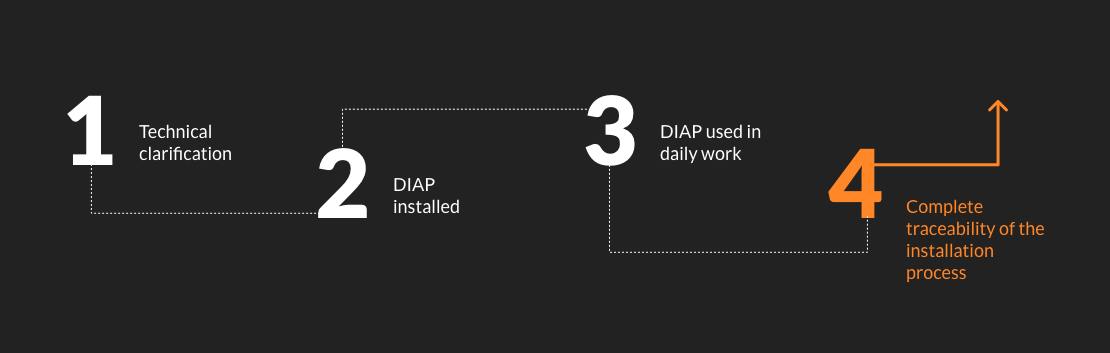

Providing complete traceability of wind turbine installations with DIAP

ENABL A/S has introduced DIAP to their client who is now collecting data on how the installation of the wind turbine’s main components has proceeded. The data ensures complete traceability of the installation process and plays an important part in the documentation of the process.