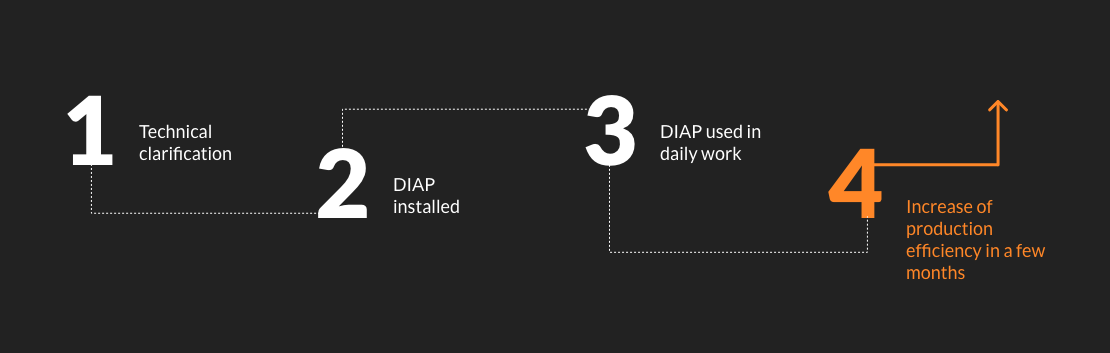

DIAP helps to improve productivity

At Novozymes, DIAP is used to collect and analyze OEE (Overall Equipment Effectiveness) data on 6 packaging lines. In just a few months, this has resulted in an increase of production efficiency. The company is now implementing DIAP on other packaging lines.