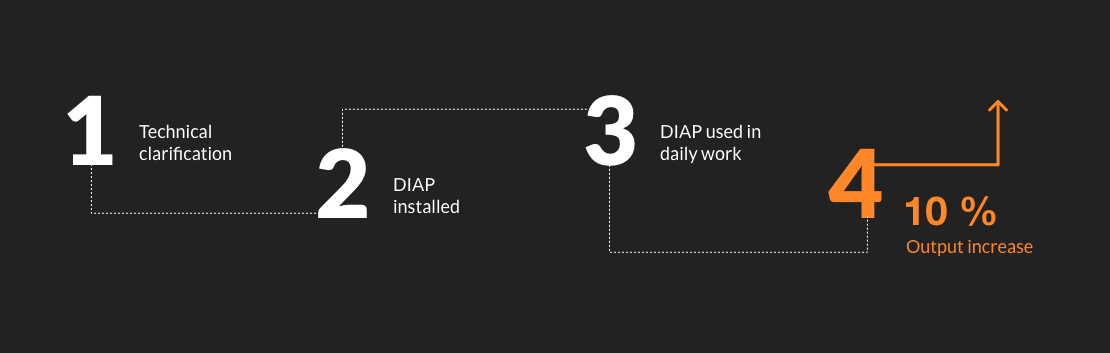

Data collection with strong potential

For data collection and calculation of OEE on 4 state-of-the-art SMT production lines, DIAP was the futureproof choice for the global EMS manufacturer GPV. By measuring OEE alone, GPV has in only 6 months been able to increase their output by 10%