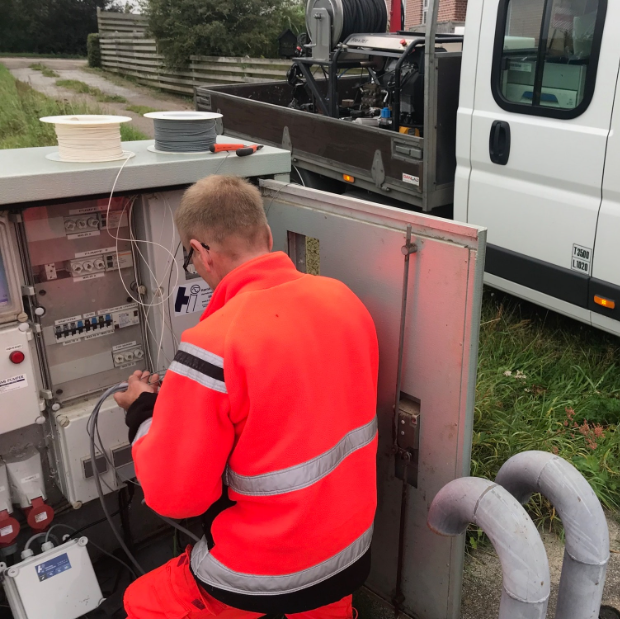

DIAP is used to predict pump breakdowns and improve efficiency

Through a close partnership with Danish utility company Skanderborg Forsyning, DIAP has been running a test project with monitoring of wastewater pump vibrations. The collected data reveals information about the current condition of a pump and is used to spot future breakkdowns.