On-demand remote service brings ENABL closer to the customer

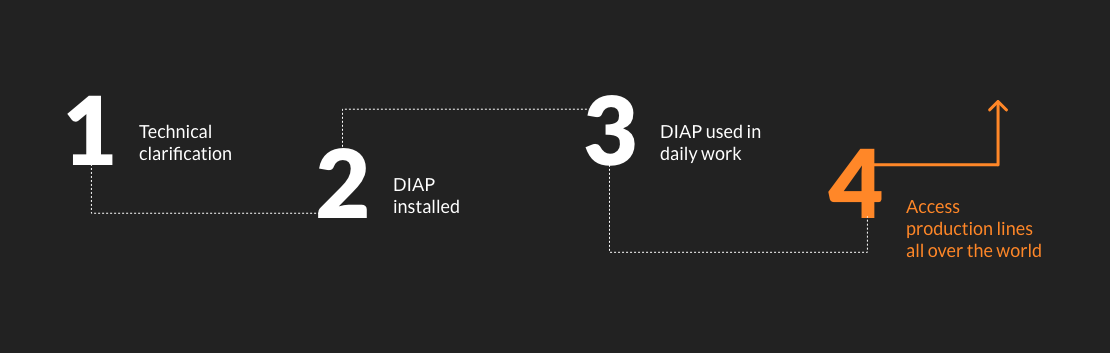

The DIAP remote access application allows ENABL A/S to access production lines all over the world and offer their customers 24/7 support and service from their Danish headquarter.

The DIAP remote access application allows ENABL A/S to access production lines all over the world and offer their customers 24/7 support and service from their Danish headquarter.

Customer satisfaction and 24/7 service go hand in hand. Knowing that ENABL is always just a call and a screen away means greater security for their customer. But what is just as valuable for ENABLs’ customers is that the production line is always running.

“We do not need specialists at all production sites. By letting our trained technicians and engineers in Denmark connect to machines all over the world we can fix the problems much faster and easier. That gives our client a lot of security, while it minimizes downtime,” says Senior Service Manager Michael Lund Gregersen.

ENABLs’ customer is a global wind turbine manufacturer. In order to collect data and visualize the optimization potential, DIAP is installed on a PCB plant for cutting carbon fiber planks into different lengths and profile milling in Portugal. These carbon fiber planks are used for manufacturing wind turbine blades.

With the installation of DIAP and the remote access application, the production managers are able to monitor the system at anytime and anywhere. All it requires is a PC, tablet, or smartphone and an internet connection.

In a global world with high competition, service providers must constantly work to create and maintain positive customer relationships. One way to do this is striving to create a partnership with your customer improving interpersonal communication. Delivering the best possible customer service leads to higher levels of customer satisfaction and retention.

According to Michael Lund Gregersen from ENABL, this is one of the key benefits of DIAP remote access.

“We are constantly striving to strengthen the partnership with each customer by showing that we are working in their best interests. We always aim to meet their needs, wants, and expectations. The DIAP remote access application is letting us do just that by making the dialogue and service visual, simple and on-demand”, Michael Lund Gregersen adds.

ENABL plans to use the remote access application integrated with the DIAP solution on all customers in the future.

We do not need specialists at all production sites. By letting our trained technicians and engineers in Denmark connect to machines all over the world we can fix the problems much faster and easier. That gives our client a lot of security, while it minimizes downtime ”

Michael Lund Gregersen, Senior Service ManagerUsing DIAP, ENABL is always close to the customer and many problems can be solved via remote access. Combining this service with data collection of production is game-changing. The reduction of travel costs is significant, and it is possible to plan the maintenance efficiently.

Delivering the best possible customer service leads to higher levels of customer satisfaction and retention.

The PCB plant for cutting carbon fiber planks into different lengths and profile milling in Portugal. These carbon fiber planks are used for manufacturing wind turbine blades.

Solutions designs and manufactures equipment for production, transport, installation, and service of wind turbines. The company delivers equipment to global customers in the wind industry and has test and assembly facilities in Denmark, UK, and China.

Business Administrator

+45 25 41 79 04

jdha@dataintel.dk